Choice Precision Machine, Inc. Scores Productivity Hat Trick with Emuge Cutting Tools

Post Date: 29 Aug 2009 Viewed: 806

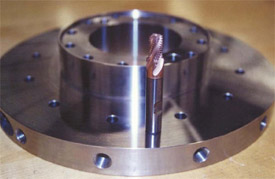

Tapping, thread milling and end milling applications create productive new machining solutions.

Choice Precision Machine is a state-of-the-art, mid-sized, CNC job shop, which manufactures precision components for an impressive list of customers, including builders of papermaking, folding and insertion machines. Always with an eye on performance, Choice truly understands the value and operational enhancements that high quality tools provide. They have been using Emuge Taps since 1997 and have come to rely on Emuge for their tapping expertise. In fact, they now exclusively use Emuge Taps and Tap holders in their jobs that involve alloy steels, stainless steels, titanium, and even Inconel. Rick Hujcs, Choice's Tooling Engineer, comments, "I knew I could call Andre Benson, Project Manager at Emuge, with a tapping problem, and get the right tap with the necessary information to complete the job." Hujcs soon found that Emuge's expertise went well beyond tapping to include effective thread milling and machining applications.

Tapping into the Problem

In June 2003 Choice encountered a specific tapping application on a Mazak HMC which called for a series of _-18 NPT threads in 4140 heat-treated material. A counter-bore geometry was required above the thread, which made this application difficult. First, Emuge tried a specific tap geometry to tackle the problem - a slow spiral design Rekord D-VA-TiN. This tap cut well but was re-cutting chips, which was in turn chipping and breaking taps. The solution? Emuge introduced a tap with coolant-through capability and an appropriate tap holder, which improved performance but still proved unreliable in terms of tool life.

Enter the Emuge experts. Bensen called Choice's Sales Engineer, Tom Kowalski, and a trip was scheduled to Choice Precision Machine to look over the application up close. Mark Hatch, Emuge's Manager of Thread-milling, was also consulted and he agreed to provide a thread-milling solution as an optional fix. Mark specified a thread-mill and tool holder, and wrote a program for the application before the trip to Choice.

When Kowalski arrived on-site at Choice Precision Machine, he discovered that many taps had been tried from many different manufacturers and all had failed. Hujcs and Kowalski reviewed the machine and part fixturing, and immediately decided to skip right to the thread milling solution. The program was entered into the machine, some parts were run, and the thread mill performed great. Choice quickly discovered that by utilizing thread milling the chips were extremely small, and with added coolant through the tool, there weren't any chips in the hole or on the tool. This eliminated the re-cutting of chips and made the threading process very smooth and reliable. Thread milling also provided a quality threads and a longer tool life. In this application, a thread mill averages 600 threads, while a tap never produced more than 20 threads. The thread mill can also be re-sharpened and re-coated for a second run.

Mill It For All It's Worth

Having proven the quality and value of their taps and thread milling products, Emuge set their sights on Choice's milling applications. They were soon presented with a simple side/end milling application in 1" 304 Stainless Steel. Their challenge was to reduce tooling time and the number of required tools from two to one. The following parameters were specified:

Current Method

Roughing Tool: 1 inch diameter square shoulder helical insert mill with two inserts

Vc = 300 SFM

S = 1150 rpm

Ae = .125

Ap = .600 max ( *2 Passes needed )

Fz = .005 cpt

F = 11.5 ipm

Current Method

Finishing Tool: 5/8 diameter 4 flute solid carbide tool

Vc = 150 SFM

S = 915 rpm

Ae = .010

Ap = 1.00

Fz = .002 cpt

F = 7.32 ipm

Tom Kowalski consulted with Stephen Jean, Emuge's Product Manager for Milling Tools and Jean recommended a single high performance cutter, featuring an extremely high helix angle and a high flute count. It was perfect for end milling tough materials with very little side pressure. The tool and the following parameters were submitted to Choice:

Roughing

Vc = 350 SFM

S = 1800 rpm

Ae = .125

Ap = 1.00 ( * only one pass needed )

Fz = .0028 cpt

F = 30 ipm

Finishing

Vc = 350 SFM

S = 1800 rpm

Ae = .010

Ap = 1.00

Fz = .0056 cpt

F = 60 ipm

The cutter was put to the test and ran the complete job without incident and with very little wear. Rick Hujcs stated, "The cutter cut so smoothly it was hard to determine whether or not it was actually working." He also noticed that the spindle load meter barely showed any additional load. But did the cutter accomplish its goal? Choice saw an 83% decrease in cycle time and they eliminated the use of two separate tools with a single Emuge cutter.

Cut the Chatter

Emuge noticed that Choice could obtain productivity gains in other areas too after they investigated some larger applications in the shop. Hujcs showed them a routine large volume job in 4140 heat-treated steel material. Rick described a roughing operation, which he characterized as loud and extremely slow with their current square shoulder insert cutter. The milled part starts out as a round 9-inch diameter piece of bar stock; it is then milled into an oval shape in a Mazak MTV-515/40 VMC. Emuge examined the running parameters to determine if they could offer an improvement.

Material: 4140 HT steel

Machine: Mazak VMC, CAT-50, 20hp, model MTV-515/40

Stock thickness: .472

Linear length of cut per part = 23 inches

Current Method

Roughing Tool: 1 inch diameter square shoulder helical insert tool with two inserts

Vc = 400 SFM

S = 1528 rpm

Ap = .236 ( two passes needed )

Ae = .560

Fz = .004 cpt

F = 12.22 ipm

Cycle Time is 226 seconds

After reviewing the current process and analyzing the parameters, Emuge looked for a solution that would eliminate the chatter, vibration and noise associated with this application. The Time-S-Cut seemed a likely fit and the trials began. After experimenting with water-soluble coolant versus cold air, Emuge demonstrated that insert life drastically improved with cold air. Improvements were also made to the part clamping fixtures, and Choice was sent the following cut parameters:

Time-S-Cut Method

Time-S-Cut Tool: #9235.05204 52mm diameter cutter with 4 inserts #9588A.12525 type PE6-TiAlN 12.5mm

Vc = 700 SFM

S = 1306 rpm

Ap = .040 ( ten passes required )

Ae = .560

Fz = .050

F = 261 ipm

Cycle Time is 53 seconds

The Time-S-Cut approach shaved 170 seconds off the primary roughing cycle for each part. Using the new cutter also drastically reduced the spindle load and significantly reduced the noise and vibration produced by their previous cutting tool.

Next, Choice used a solid carbide Emuge tool to eliminate the radius and shoulder material, which was left at the bottom of the part due to the Time-S-Cut geometry. This secondary roughing pass adds 40 seconds to the total cycle time, for a final savings of 130 seconds per part or a 58% cycle-time savings.

Choice realized a total savings of $1.78 per part. The initial investment in the cutter and arbor was paid for after approximately 400 parts and the job runs more smoothly and quietly with less stress on the machine.

Twice Charmed

The initial tests with the Time-S-Cut System involved the larger Emuge insert size 12.5mm CAT-50 machine. The smaller 8mm size insert was then applied to a milling operation on a CAT-40 machine in 12L14 material to manufacture a machine part. The machine is a Mazak Nexus 510C Vertical Milling Center with a 25hp motor and a maximum speed of 12,000 rpm. On this application the challenge was again to generate cost savings with reduced cycle time. A secondary savings is realized by consolidating the number tools needed to finish the machining task from six separate tools to only four tools.

The timesaving proved to be 129 seconds -- or 32% -- per part for a $1.79 per part savings in cycle time. Additionally, only one insert change will complete an entire run of 1,000 pieces annually. The machine runs smooth in the heaviest cut and the entire milling operation is carried out with just cold air as coolant. Tool life has also proven to be excellent for this application.

Tooling Solutions that Deliver

Choice Precision is a perfect example of how Emuge's expertise can solve specific machining problems for their customers - whether it's a problem with thread mills, end mills or toolholders, they delivered the solution. "We just kept challenging them with new applications and each time they found a way to refine the process and save us money," states Rick Hujcs. "Now I consider Emuge much more than a high performance tapping source."