Easy grinding of single crystal c-plane sapphire wafers

Post Date: 18 Sep 2009 Viewed: 976

Introduction

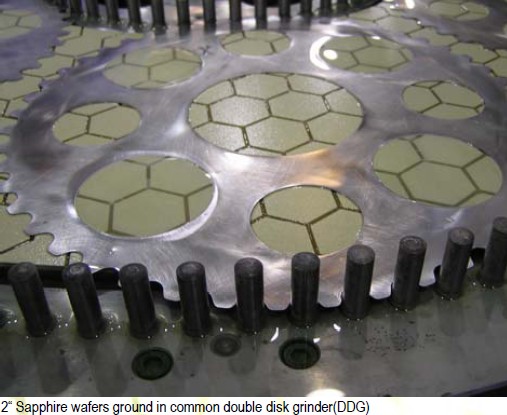

Single crystal sapphire (Al2O3) is widely used to produce optical windows and laser components [A-plane, Rplane]. For this emerging application it is used as prime substrate for growing gallium nitride films on the [Cplane] face for the manufacture of blue LEDs.

Due to the increased hardness and fracture toughness the grinding processes of c-plane sapphire becomes more difficult. Additional requirements in the prime wafer manufacture like grinding at very low forces, low speed and self sharpening behaviour of the abrasive tool, makes the manufacture of a diamond super abrasive grinding structure for this material very challenging.

As the technology leader in the manufacture of vitrified super abrasives, Meister Abrasives has undertaken process trials on this difficult material and developed a new innovative range of vitrified diamond super abrasives that enable coarse and fine grinding of these

sapphire wafers.

Application from coarse to fine grinding

The objective of fine grinding is to avoid the costly lapping processes and reduce or eliminate the long CMP or polishing process by using ultra fine diamond crystals in the grinding wheel.

Benefits of vitrified diamond bonding

• Higher and more consistent precision stock removal

• Very low grinding forces

• Free cutting and self sharpening capabilities

• Better process control

• Improved flatness control