Remarkable achievements,splendid future.

Post Date: 21 Jan 2009 Viewed: 1623

Remarkable achievements, splendid future Celebrating the 45th anniversary of synthetic diamond of China Li Zhihong, Zhao Bo, Yi Yunlei, Wang Qin,Hua Shujie,Zhang Hui (Zhengzhou Research Institute for Abrasives and Grinding,Zhengzhou 450013,China)  Li Zhihong, male, Professor Grade Senior Engineer, Deputy Chief Engineer, General Secretary of Superhard Material (Industrial Diamond) Association of China CMTBA, engaged in research and technical management work, has published 3 books by publishing house,more than 10 books by the industry and 30 papers. Abstract:The development of China as the world's manufacturing house is best exemplified in the industry of diamond superabrasives. Diamond is indispensable in the creation of industrial infrastructure, including the construction of roads and building of houses. The world's diamond was provided mainly by countries outside China in last century.However, a"great leap forward" has taken shape with rapid expansion in Chinese diamondmaking capabilities from the enlargement of the equipment (cubic presses) and improvements in diamond yield and product quality in the end of last century. At the turn of this century, China outpaced the rest world combined in the total diamond output, became the largest producer in the world indubitably. In 2007, China produced nearly 4.4 billion carats, 80% of the world's diamond total output. The Chinese diamond well accepted in the world can be seen in the export statistics of China & import statistics of developed countries in this paper. For example, 59% of USA imported diamonds were from China in 2007; in Japan, 40%. This report contains a survey of some main industrial sectors that use diamond superabrasives. Overall, 22 tables and figures are used to portray the many facets of superabrasives, including cubic boron nitride. The report also discusses several challenges facing Chinese diamonds, such as the vast price difference between imported diamond grit produced outside China and domestic supply. This paper also presents an outlook of the future development of the Chinese superabrasives industry basing on the Chinese macroeconomics and the recent data of the endusers as well as their future development trend. The paper concludes by proposing that although remarkable achievements have been made in the past 45 years, given the fact that Chinese superabrasives industry still lags behind that from the advanced countries on a multitude of variables, further endeavor should be made to make China a super country in the superabrasives industry in the world. Keywords:Industrial diamond; superabrasives; cubic press; cubic boron nitride; diamond saws The Chinese superabrsives industry has been advanced significantly in the past 45 years both in terms of technology and scale thanks to the great effort made by several generations. Chinese superabrasives can not only meet the needs from the domestic market but also are being exported to all over the world, which is a great contribution to the world economy. The annual output of Chinese synthetic diamond up to now is approaching 4 billion carats and this annual output has undoubtedly become the number one since year 2000. A brief review of the superabrasives industry shows many splendid chapters: The first generation technology was marked by the invention of cubic press synthesizing diamond and CBN in China. The second generation technology was marked by the enlargement of equipment and upgrading of reaction chamber and synthesizing technology. The cubic press was enlarged 3~6 times; output per cycle was improved by 10 times; and the quality of the diamonds was better off as well. The third generation technology was marked by the synergy of the advantages of both belt press and cubic press; powder technology; and indirect heating technology. These advancements enabled the output per cycle doubled and the quality improved by leaps and bounds. The quality of some products reached international standard. In the meantime, the production cost was reduced significantly. Along with the advancements of various superhard materials, the final products were also being improved both in terms of quality and variety, making it possible for the Chinese to compete with the international players. However, when can we achieve the goal that we set forth a long time ago to become a super country in the superabrasives industry? What is the future trend? How can we make more contributions to the world economy together with our international counterparts? These are some of the questions raised by the people who care for this industry. This paper intends to provide a brief analysis to address these questions and serve as a reference. 1 A review of the industry in the 21st century 1.1 Incomplete statistics and analyses Since the millennium, with the booming Chinese macro economy, investment, infrastructure, and exports, the superabrasives industry has overcome the downsides caused by inflation, electricity shortage, decreasing selling price etc. The major measures of the industry hit record high every year. Both the production and sales, are contributing to the satisfactory performances of the prosperous industry.

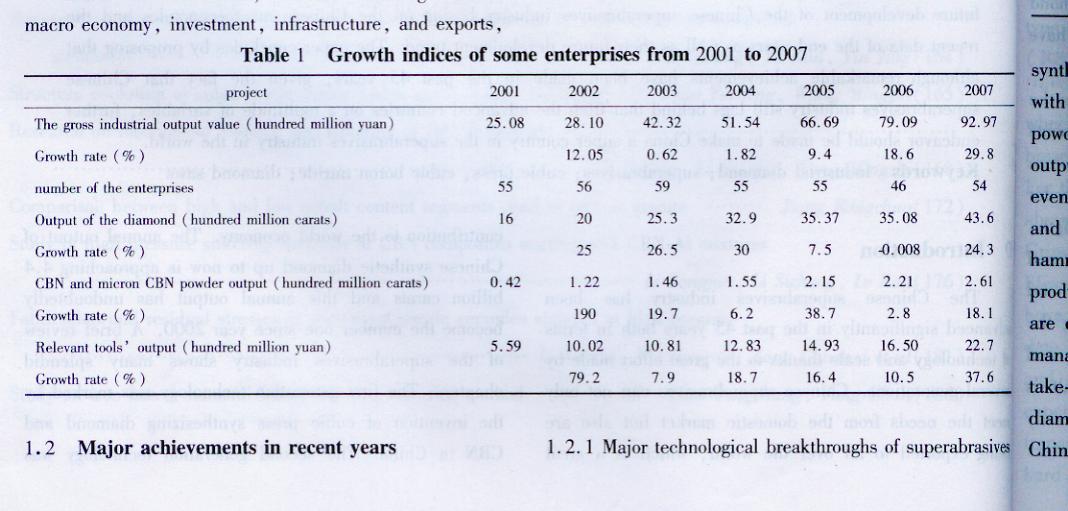

Li Zhihong, male, Professor Grade Senior Engineer, Deputy Chief Engineer, General Secretary of Superhard Material (Industrial Diamond) Association of China CMTBA, engaged in research and technical management work, has published 3 books by publishing house,more than 10 books by the industry and 30 papers. Abstract:The development of China as the world's manufacturing house is best exemplified in the industry of diamond superabrasives. Diamond is indispensable in the creation of industrial infrastructure, including the construction of roads and building of houses. The world's diamond was provided mainly by countries outside China in last century.However, a"great leap forward" has taken shape with rapid expansion in Chinese diamondmaking capabilities from the enlargement of the equipment (cubic presses) and improvements in diamond yield and product quality in the end of last century. At the turn of this century, China outpaced the rest world combined in the total diamond output, became the largest producer in the world indubitably. In 2007, China produced nearly 4.4 billion carats, 80% of the world's diamond total output. The Chinese diamond well accepted in the world can be seen in the export statistics of China & import statistics of developed countries in this paper. For example, 59% of USA imported diamonds were from China in 2007; in Japan, 40%. This report contains a survey of some main industrial sectors that use diamond superabrasives. Overall, 22 tables and figures are used to portray the many facets of superabrasives, including cubic boron nitride. The report also discusses several challenges facing Chinese diamonds, such as the vast price difference between imported diamond grit produced outside China and domestic supply. This paper also presents an outlook of the future development of the Chinese superabrasives industry basing on the Chinese macroeconomics and the recent data of the endusers as well as their future development trend. The paper concludes by proposing that although remarkable achievements have been made in the past 45 years, given the fact that Chinese superabrasives industry still lags behind that from the advanced countries on a multitude of variables, further endeavor should be made to make China a super country in the superabrasives industry in the world. Keywords:Industrial diamond; superabrasives; cubic press; cubic boron nitride; diamond saws The Chinese superabrsives industry has been advanced significantly in the past 45 years both in terms of technology and scale thanks to the great effort made by several generations. Chinese superabrasives can not only meet the needs from the domestic market but also are being exported to all over the world, which is a great contribution to the world economy. The annual output of Chinese synthetic diamond up to now is approaching 4 billion carats and this annual output has undoubtedly become the number one since year 2000. A brief review of the superabrasives industry shows many splendid chapters: The first generation technology was marked by the invention of cubic press synthesizing diamond and CBN in China. The second generation technology was marked by the enlargement of equipment and upgrading of reaction chamber and synthesizing technology. The cubic press was enlarged 3~6 times; output per cycle was improved by 10 times; and the quality of the diamonds was better off as well. The third generation technology was marked by the synergy of the advantages of both belt press and cubic press; powder technology; and indirect heating technology. These advancements enabled the output per cycle doubled and the quality improved by leaps and bounds. The quality of some products reached international standard. In the meantime, the production cost was reduced significantly. Along with the advancements of various superhard materials, the final products were also being improved both in terms of quality and variety, making it possible for the Chinese to compete with the international players. However, when can we achieve the goal that we set forth a long time ago to become a super country in the superabrasives industry? What is the future trend? How can we make more contributions to the world economy together with our international counterparts? These are some of the questions raised by the people who care for this industry. This paper intends to provide a brief analysis to address these questions and serve as a reference. 1 A review of the industry in the 21st century 1.1 Incomplete statistics and analyses Since the millennium, with the booming Chinese macro economy, investment, infrastructure, and exports, the superabrasives industry has overcome the downsides caused by inflation, electricity shortage, decreasing selling price etc. The major measures of the industry hit record high every year. Both the production and sales, are contributing to the satisfactory performances of the prosperous industry.  Table 1 indicates the growth indices of some enterprises from 2001 to 2007. The output of synthetic diamond and CBN can represent the level of the whole industry; while the gross industrial output value and the relevant products’ output can’t represent the level of the whole industry because of the missing data of some large and mediumsized enterprises. However, its trend can represent the level of the whole industry. Table 1 shows although the gross industrial output value, diamond output, CBN and the micron diamond powder output and relevant products’ output increase unbalancedly annually, on a whole, we can still see a rapidly rising trend. The gross industrial output value has increased by 2.7 times; diamond output increased by 1.7 times, CBN and micron CBN output increased by 5.2 times and relevant products output increased by 3.1 times. The data show that the lowest annually increasing ratio is 18% (diamond), the highest annually increasing ratio is 35%(CBN & micron CBN), higher overall growth of the superabrasives industry than the growth of GDP in China. Therefore, the superabrasives industry is a high growth industry. 1.2 Major achievements in recent years 1.2.1 Major technological breakthroughs of superabrasives 1.2.1.1 Great advancements in production technology and quality of monocrystalline synthetic diamond Basing on the TI and TTI indices for the premium quality synthetic diamonds, the quality is approaching the international standard with TITTI value ≤3%, percentage of the output per cycle around 10%. For the middle grade diamonds which are being produced in mass quantity, the TITTI value is ≤10%. In particular, a series of technological problems have been solved in order to produce the premium grade diamond (20/30) with the optimum design of the synthesizing equipment, pressure transmission medium etc. These advancements have enabled us to compete in the world market with better products and lower price. The history of Chinese being unable to produce DMD product (one of the Chinese models) came to an end. To the best of the author’[KG-*5]s knowledge, the bigger size and higher grade monocrystalline diamond 8/10 ~ 18/20 has been launched in small quantity.

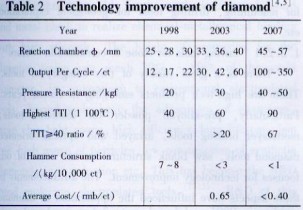

Table 1 indicates the growth indices of some enterprises from 2001 to 2007. The output of synthetic diamond and CBN can represent the level of the whole industry; while the gross industrial output value and the relevant products’ output can’t represent the level of the whole industry because of the missing data of some large and mediumsized enterprises. However, its trend can represent the level of the whole industry. Table 1 shows although the gross industrial output value, diamond output, CBN and the micron diamond powder output and relevant products’ output increase unbalancedly annually, on a whole, we can still see a rapidly rising trend. The gross industrial output value has increased by 2.7 times; diamond output increased by 1.7 times, CBN and micron CBN output increased by 5.2 times and relevant products output increased by 3.1 times. The data show that the lowest annually increasing ratio is 18% (diamond), the highest annually increasing ratio is 35%(CBN & micron CBN), higher overall growth of the superabrasives industry than the growth of GDP in China. Therefore, the superabrasives industry is a high growth industry. 1.2 Major achievements in recent years 1.2.1 Major technological breakthroughs of superabrasives 1.2.1.1 Great advancements in production technology and quality of monocrystalline synthetic diamond Basing on the TI and TTI indices for the premium quality synthetic diamonds, the quality is approaching the international standard with TITTI value ≤3%, percentage of the output per cycle around 10%. For the middle grade diamonds which are being produced in mass quantity, the TITTI value is ≤10%. In particular, a series of technological problems have been solved in order to produce the premium grade diamond (20/30) with the optimum design of the synthesizing equipment, pressure transmission medium etc. These advancements have enabled us to compete in the world market with better products and lower price. The history of Chinese being unable to produce DMD product (one of the Chinese models) came to an end. To the best of the author’[KG-*5]s knowledge, the bigger size and higher grade monocrystalline diamond 8/10 ~ 18/20 has been launched in small quantity.  The improvement of the synthetic diamond synthesizing technology can be seen from table 2: Along with the enlargement of the reaction chamber as well as powder and indirect heating technologies, the current output per cycle is mostly 5~8 times that in 1998 and even more in some enterprises. The compressive strength and TTI have been increased by more than one time and hammer consumption decreased by 86% as well as the production cost reduced by 38.5%. These advancements are due to the update of technology and refinement of management. If we may say that before 2003, it was the takeoff period for the quantity of China's synthetic diamonds, it has been a takeoff period for the quality of China's synthetic diamonds after 2003. From this we see our hope of becoming a super country of superabrasives working shoulder to shoulder with rest of the international leaders is coming true. 1.2.1.2 Breakthrough in CBN monocrystal manufacturing technology and quality

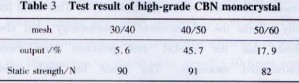

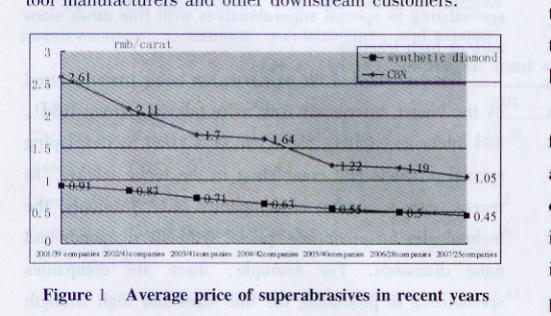

The improvement of the synthetic diamond synthesizing technology can be seen from table 2: Along with the enlargement of the reaction chamber as well as powder and indirect heating technologies, the current output per cycle is mostly 5~8 times that in 1998 and even more in some enterprises. The compressive strength and TTI have been increased by more than one time and hammer consumption decreased by 86% as well as the production cost reduced by 38.5%. These advancements are due to the update of technology and refinement of management. If we may say that before 2003, it was the takeoff period for the quantity of China's synthetic diamonds, it has been a takeoff period for the quality of China's synthetic diamonds after 2003. From this we see our hope of becoming a super country of superabrasives working shoulder to shoulder with rest of the international leaders is coming true. 1.2.1.2 Breakthrough in CBN monocrystal manufacturing technology and quality  Before 2007, no highquality CBN monocrystal bigger than 40 mesh was produced in China. Though there were some 40/45 mesh CBN monocrystals, the output was very low as well as the quality which could not meet the demand for highefficiency polishing application. The level of one Chinese company's highgrade big mesh CBN monocrystal launched in 2007 is shown in table 3. Experiment conditions:6×20 MN cubic press,diameter of the reaction chamber 40 mm,accuracy of the power control ±0.[KG-*6]01 kW,accuracy of the pressure control ±0.01 MPa, 3356 synthesizing cycles,average output per cycle 85cts. The crystals are in perfect shape. Most crystals are blocky and few crystals are flat. This product has been put into mass production and is well received by the overseas customers. Table 3 shows that: percentage of 30~60 meshes is as high as 69.2%, static strength is as high as 82~90 N. Highgrade and big mesh 20/30 CBN monocrystal has filled the gap in China. 1.2.1.3 Small and medium sized enterprises (SMEs) specializing in special superabrasives with fine mesh sizes and/or high fragility Because most of the saw grits are being manufactured by the bigger enterprises with more talents, strong R&D, and intensive capital, SMEs can only excel by developing special products and completing in the niche market. In recent years a number of companies have developed the technologies for producing special synthetic diamonds and nano diamonds. For example, there are companies specializing in producing the fine sizes and high strength or high fragility diamonds (less than 80/100) for polishing and grinding applications. The range of the mesh size can be controlled around 140/170 and 170/200 according to the market demand. Some companies can control the peak value to 230/270, 270/325 and even finer. 600 mesh and even 800 mesh diamonds can be directly synthesized in mass production. This series of products have been supplied to overseas for years. The production technology of this series of products is different in terms of synthesizing, acid washing, sorting and testing processes from that of saw grit production. This trend not only reflects the advancement in technology, but also shows that the market and products have been restructured rationally. The profit for each press synthesizing fine grits is even higher than that synthesizing saw grits. 1.2.1.4 Average price going down due to technology advancement and market competition results in benefiting the customers. Figure 1 shows the average price of superabrasives from 2001~2007. From this figure we can see that the average selling price has been reduced from 0.91 rmb/ct to 0.45 rmb/ct with a decrease rate of 51%ï¼› The average selling price for CBN has been reduced from 2.61 rmb/ ct to 1.05 rmb/ct with a decrease rate of 60%. Market competition is one of the driving forces but technology is the major driving force for the price decline. Suppose the average production cost for synthetic diamonds was 0.65 rmb/ct as it was in 2003(see table 2), how is it possible to sell at 0.45 rmb /ct?Technology advancement has contributed to quality improvement, selling price decline, and companies’ profit! This also has promoted the wider application of superabrasives and benefited the diamond tool manufacturers and other downstream customers.

Before 2007, no highquality CBN monocrystal bigger than 40 mesh was produced in China. Though there were some 40/45 mesh CBN monocrystals, the output was very low as well as the quality which could not meet the demand for highefficiency polishing application. The level of one Chinese company's highgrade big mesh CBN monocrystal launched in 2007 is shown in table 3. Experiment conditions:6×20 MN cubic press,diameter of the reaction chamber 40 mm,accuracy of the power control ±0.[KG-*6]01 kW,accuracy of the pressure control ±0.01 MPa, 3356 synthesizing cycles,average output per cycle 85cts. The crystals are in perfect shape. Most crystals are blocky and few crystals are flat. This product has been put into mass production and is well received by the overseas customers. Table 3 shows that: percentage of 30~60 meshes is as high as 69.2%, static strength is as high as 82~90 N. Highgrade and big mesh 20/30 CBN monocrystal has filled the gap in China. 1.2.1.3 Small and medium sized enterprises (SMEs) specializing in special superabrasives with fine mesh sizes and/or high fragility Because most of the saw grits are being manufactured by the bigger enterprises with more talents, strong R&D, and intensive capital, SMEs can only excel by developing special products and completing in the niche market. In recent years a number of companies have developed the technologies for producing special synthetic diamonds and nano diamonds. For example, there are companies specializing in producing the fine sizes and high strength or high fragility diamonds (less than 80/100) for polishing and grinding applications. The range of the mesh size can be controlled around 140/170 and 170/200 according to the market demand. Some companies can control the peak value to 230/270, 270/325 and even finer. 600 mesh and even 800 mesh diamonds can be directly synthesized in mass production. This series of products have been supplied to overseas for years. The production technology of this series of products is different in terms of synthesizing, acid washing, sorting and testing processes from that of saw grit production. This trend not only reflects the advancement in technology, but also shows that the market and products have been restructured rationally. The profit for each press synthesizing fine grits is even higher than that synthesizing saw grits. 1.2.1.4 Average price going down due to technology advancement and market competition results in benefiting the customers. Figure 1 shows the average price of superabrasives from 2001~2007. From this figure we can see that the average selling price has been reduced from 0.91 rmb/ct to 0.45 rmb/ct with a decrease rate of 51%ï¼› The average selling price for CBN has been reduced from 2.61 rmb/ ct to 1.05 rmb/ct with a decrease rate of 60%. Market competition is one of the driving forces but technology is the major driving force for the price decline. Suppose the average production cost for synthetic diamonds was 0.65 rmb/ct as it was in 2003(see table 2), how is it possible to sell at 0.45 rmb /ct?Technology advancement has contributed to quality improvement, selling price decline, and companies’ profit! This also has promoted the wider application of superabrasives and benefited the diamond tool manufacturers and other downstream customers.  The production technology and quality of PCD,PDC,PCBN,CVD,and nano diamonds etc have been improved significantly in recent years. The application scope has become wider and wider. However, the output still accounts for little in the whole industry we therefore skip this part. 1.2.2 Various superabrasives tools emerging with improved technology and quality. Because of the large number of the variety of superabrasives tools and their applications, as well shortage of complete statistics, overall data and analyses cannot be given. After tracing about 40 tool manufacturers, the output of sawing tools for stone & construction industries is about 60%~70% of the total superabrasives tools,that of cutting and grinding tools for machining is about 15%,that of the drilling tools(excluding petroleum, natural gas drilling) for geological exploration is about 2%,that of other tools accounts for 10%~20%. Though these percentages might not be very accurate, but they can represent the overall picture. This paper tries to give examples of the technology advancement of the tools, categorizing them into sawing tools for stone & construction, cutting and grinding tools for machining, drilling tools for geological exploration etc. 1.2.2.1 sawing tools for stone & construction sectors There is a great variety of this category of tools. There are hightech products emerging in recent years. Particularly, prealloyed powder for diamond tools, monolayer brazing tools, arrayed and optimal oriented diamond tools, saw blank structure etc are some of our focuses for technology improvement. The advancements in these aspects have influenced the application of diamond tools in a positive way and remarkable achievements have been made. (1) Pre-alloyed powder. Pre-alloyed powder has the following advantages:evenly distributed metal elements avoiding overconcentrating, making the matrix structure even and functionality consistent; well alloyed powder imparting the matrix higher hardness and impact strength, improving the compressive strength of the sintered products, the holding strength to the diamonds and lifespan of the tool; high sintering vitality reducing the sintering temperature, shortening the sintering time and saving the energy. Moreover, precious metal cobalt is replaced by iron or copper which can not be easily oxygenized. The production procedure becomes easier. The concentration of diamonds is reduced by 15~20% as well as the production cost is also reduced[79].In the late 1990s, pre-alloyed powder was first introduced by the international players followed by the Chinese. In the 21st century, we have made progress in this area. We now have prealloyed powder made with vaporization and cosedimentation well received by the market. This, as well as the diamond quality risen high and the price lowered down, makes the level of the tool manufacturing rise a lot. Experiment shows[10ï¼½that the sharpness and lifespan of the 350 diamond saw blades made with copper based prealloyed powder when cutting mediumhard granite can be increased by 25% compared with conventional ones. The sharpness and lifespan of the 1600 diamond blades made with iron based prealloyed powder when cutting mediumhard granite can be increased by 60% compared with conventional ones. (2) Monolayer brazed diamond tool. Monolayer brazing makes it possible for the synthetic diamond, bond and metal blank to realize chemicalmetallurgical binding with high strength. The height of protrusion for the abrasive grains can reach 70%~80% of the grain diameter. In comparison to conventional electroplated tools, brazed tools have the advantages of sharpness, large chiphold space,high efficiency,long lifespan,jam free,high usage of particles,low consumption of synthetic diamonds,cost reduction etc. This has become the R&D trend replacing electroplated tools.[1113]. R&D of this type of tools started from mid and late 1980s in China(R&D of this type of tools abroad started in 1990s [11,12]). In 1989,40 mm brazed diamond grinding wheels were successfully produced,followed by 25 mm brazed diamond points, and diamond needl files etc[13]. For these trial products, the height of protrusion for the abrasive grains reaches 2/3 of the grain diameter. Grinding efficiency is improved by 50% and average lifespan improved by 50%. The pity is these products have not been put in mass production. The most uptodate R&D has generated two major technologies: brazing and diamond optimal (arrayed) orientation. For the experimental products 20 mm diamond brazed trepanning drill and beaded wire saw, 12 mm mediumhard granite block was drilled 500 holes by the single drill and 500~600 m2 of granite, marble and sandstone were cut by 18 m beaded wire saw. When processing the bulletproof multilayer compound board for the lightweight tank, miracles were created that diamond brazed core drill took 25 seconds to drill one hole and the line speed of brazed circular saw blade reached 1.5 m/min. The experiments proved that their processing efficiency as well as the lifespan can be improved by over 5~10 times and the major production cost can be reduced by 50%~60%[12]. Various technologies such as reducing the temperature for brazing [JP3]( from 1080 ℃ of high temperature brazing to 780 ℃ of low temperature brazing)[14], laser brazing[15]and highfrequency induction brazing were also developed. These technological achievements have been commercialized since 2003. A number of companies producing this series of saws and drills have[JP] been supplying the overseas markets in big quantities. This series of new products not only solved the difficulties of processing new compound materials, but also promoted the technological advancement. The diamond grain optional orientation technology has also triggered the R&D of multilayer arraying of diamonds for sintering segments.  (3) Diamond saw blades with multilayer arraying. According to the referencesï¼»1719],after the invention of monolayer diamond brazed tools, the diamond segments with diamonds being arrayed in the three dimensions were being introduced subsequently. The diamond automatic arraying system invented by one overseas company in December 2004 made it possible to keep the space of diamonds being 100% controlled. The lifespan of the saw blades doubled and cutting speed went up by 30%. The followings have been achieved by a domestic saw blade company in 2006 with diamonds being arrayed in three dimensions: cutting conditions,7.5 kVA bridge automatic cutting machine,rotation speed 1 700 r/m,cutting line speed 35 m/s,feeding speed 6 m/min,depth of cut 2 cmï¼›work piece 7.3 Mohs granite plate with 2cm thickness. In comparison to that of the nonarrayed saw blade, the cutting efficiency of the 400 mm arrayed diamond saw blade was improved by 30%, overall energy consumption reduced by 30%, noise reduced by 10 db, and lifespan improved by 2.[KG-*5]56 times(the experimental blade cut a total length of 1150 meters,nonarrayed blade cut a total length of 450 meters). This product has been supplied to overseas market, but because of the small number of manufacturers and the limited output, this supply does not meet the demand. Along with the advancement of R&D, improvements of automatic diamond distribution equipment, as well as the wider application of prealloyed powder, this type of products will be more and more available. And this in turn will promote the technological innovation and update of diamond saw blades and other metal bonded products, and eventually improve the manufacturing level and competitiveness of Chinese diamond products.  (4) Improvement of saw blanks. Most of the saw blanks are circular steel plates with central holes. However, is the structure the only structure that we can possibly have? This issue was raised by some intelligent people in this industry and R&D was conducted accordingly. Research shows that some special shape of holes in certain locations of the saw blanks can not only avoid deformation, but also reduce the power consumption and noise, as well as improve the sharpness and lifespan of the blades. According to the data provided by one director of the board of a company (engineering PhD) who has been engaged with saw blade technology for a long time, for the 350 mm blades and smaller ones, the sharpness can be improved by 15%,and lifespan expanded by 20%. He also provided some comparison data for two 3000 mm saw blades (thickness of the segments 12 mm) either with or without holes as shown in figure 2. 

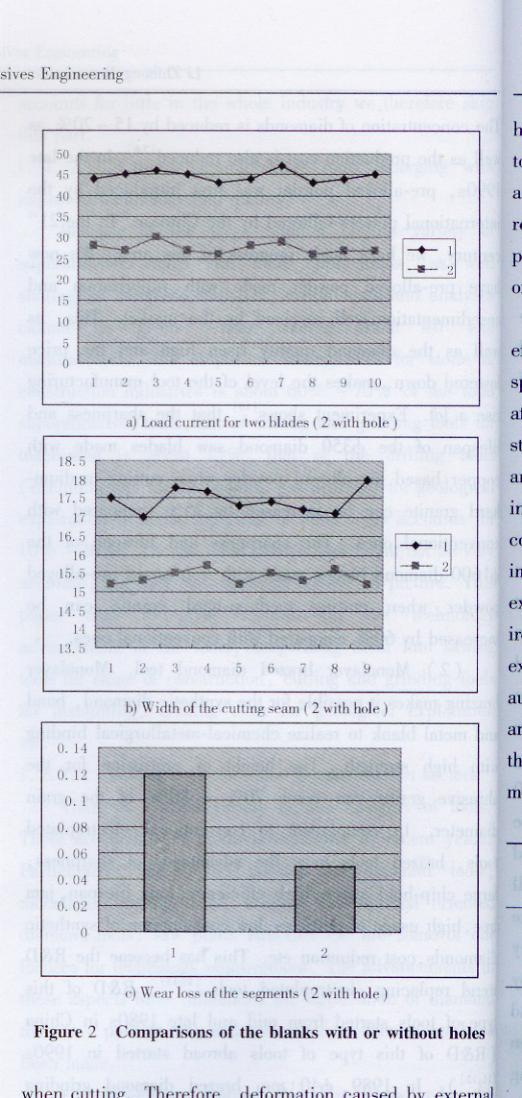

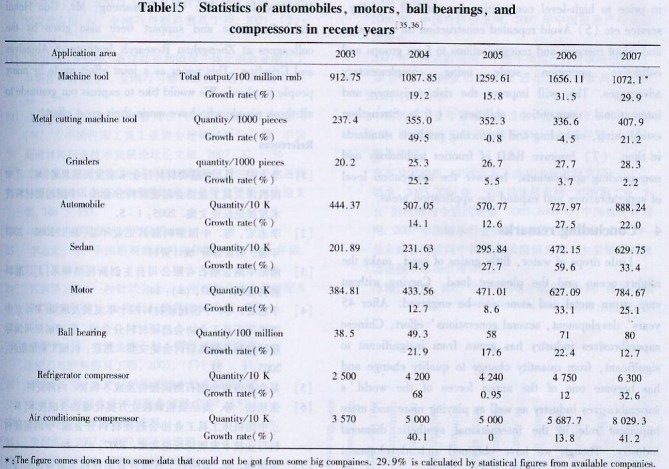

The production technology and quality of PCD,PDC,PCBN,CVD,and nano diamonds etc have been improved significantly in recent years. The application scope has become wider and wider. However, the output still accounts for little in the whole industry we therefore skip this part. 1.2.2 Various superabrasives tools emerging with improved technology and quality. Because of the large number of the variety of superabrasives tools and their applications, as well shortage of complete statistics, overall data and analyses cannot be given. After tracing about 40 tool manufacturers, the output of sawing tools for stone & construction industries is about 60%~70% of the total superabrasives tools,that of cutting and grinding tools for machining is about 15%,that of the drilling tools(excluding petroleum, natural gas drilling) for geological exploration is about 2%,that of other tools accounts for 10%~20%. Though these percentages might not be very accurate, but they can represent the overall picture. This paper tries to give examples of the technology advancement of the tools, categorizing them into sawing tools for stone & construction, cutting and grinding tools for machining, drilling tools for geological exploration etc. 1.2.2.1 sawing tools for stone & construction sectors There is a great variety of this category of tools. There are hightech products emerging in recent years. Particularly, prealloyed powder for diamond tools, monolayer brazing tools, arrayed and optimal oriented diamond tools, saw blank structure etc are some of our focuses for technology improvement. The advancements in these aspects have influenced the application of diamond tools in a positive way and remarkable achievements have been made. (1) Pre-alloyed powder. Pre-alloyed powder has the following advantages:evenly distributed metal elements avoiding overconcentrating, making the matrix structure even and functionality consistent; well alloyed powder imparting the matrix higher hardness and impact strength, improving the compressive strength of the sintered products, the holding strength to the diamonds and lifespan of the tool; high sintering vitality reducing the sintering temperature, shortening the sintering time and saving the energy. Moreover, precious metal cobalt is replaced by iron or copper which can not be easily oxygenized. The production procedure becomes easier. The concentration of diamonds is reduced by 15~20% as well as the production cost is also reduced[79].In the late 1990s, pre-alloyed powder was first introduced by the international players followed by the Chinese. In the 21st century, we have made progress in this area. We now have prealloyed powder made with vaporization and cosedimentation well received by the market. This, as well as the diamond quality risen high and the price lowered down, makes the level of the tool manufacturing rise a lot. Experiment shows[10ï¼½that the sharpness and lifespan of the 350 diamond saw blades made with copper based prealloyed powder when cutting mediumhard granite can be increased by 25% compared with conventional ones. The sharpness and lifespan of the 1600 diamond blades made with iron based prealloyed powder when cutting mediumhard granite can be increased by 60% compared with conventional ones. (2) Monolayer brazed diamond tool. Monolayer brazing makes it possible for the synthetic diamond, bond and metal blank to realize chemicalmetallurgical binding with high strength. The height of protrusion for the abrasive grains can reach 70%~80% of the grain diameter. In comparison to conventional electroplated tools, brazed tools have the advantages of sharpness, large chiphold space,high efficiency,long lifespan,jam free,high usage of particles,low consumption of synthetic diamonds,cost reduction etc. This has become the R&D trend replacing electroplated tools.[1113]. R&D of this type of tools started from mid and late 1980s in China(R&D of this type of tools abroad started in 1990s [11,12]). In 1989,40 mm brazed diamond grinding wheels were successfully produced,followed by 25 mm brazed diamond points, and diamond needl files etc[13]. For these trial products, the height of protrusion for the abrasive grains reaches 2/3 of the grain diameter. Grinding efficiency is improved by 50% and average lifespan improved by 50%. The pity is these products have not been put in mass production. The most uptodate R&D has generated two major technologies: brazing and diamond optimal (arrayed) orientation. For the experimental products 20 mm diamond brazed trepanning drill and beaded wire saw, 12 mm mediumhard granite block was drilled 500 holes by the single drill and 500~600 m2 of granite, marble and sandstone were cut by 18 m beaded wire saw. When processing the bulletproof multilayer compound board for the lightweight tank, miracles were created that diamond brazed core drill took 25 seconds to drill one hole and the line speed of brazed circular saw blade reached 1.5 m/min. The experiments proved that their processing efficiency as well as the lifespan can be improved by over 5~10 times and the major production cost can be reduced by 50%~60%[12]. Various technologies such as reducing the temperature for brazing [JP3]( from 1080 ℃ of high temperature brazing to 780 ℃ of low temperature brazing)[14], laser brazing[15]and highfrequency induction brazing were also developed. These technological achievements have been commercialized since 2003. A number of companies producing this series of saws and drills have[JP] been supplying the overseas markets in big quantities. This series of new products not only solved the difficulties of processing new compound materials, but also promoted the technological advancement. The diamond grain optional orientation technology has also triggered the R&D of multilayer arraying of diamonds for sintering segments.  (3) Diamond saw blades with multilayer arraying. According to the referencesï¼»1719],after the invention of monolayer diamond brazed tools, the diamond segments with diamonds being arrayed in the three dimensions were being introduced subsequently. The diamond automatic arraying system invented by one overseas company in December 2004 made it possible to keep the space of diamonds being 100% controlled. The lifespan of the saw blades doubled and cutting speed went up by 30%. The followings have been achieved by a domestic saw blade company in 2006 with diamonds being arrayed in three dimensions: cutting conditions,7.5 kVA bridge automatic cutting machine,rotation speed 1 700 r/m,cutting line speed 35 m/s,feeding speed 6 m/min,depth of cut 2 cmï¼›work piece 7.3 Mohs granite plate with 2cm thickness. In comparison to that of the nonarrayed saw blade, the cutting efficiency of the 400 mm arrayed diamond saw blade was improved by 30%, overall energy consumption reduced by 30%, noise reduced by 10 db, and lifespan improved by 2.[KG-*5]56 times(the experimental blade cut a total length of 1150 meters,nonarrayed blade cut a total length of 450 meters). This product has been supplied to overseas market, but because of the small number of manufacturers and the limited output, this supply does not meet the demand. Along with the advancement of R&D, improvements of automatic diamond distribution equipment, as well as the wider application of prealloyed powder, this type of products will be more and more available. And this in turn will promote the technological innovation and update of diamond saw blades and other metal bonded products, and eventually improve the manufacturing level and competitiveness of Chinese diamond products.  (4) Improvement of saw blanks. Most of the saw blanks are circular steel plates with central holes. However, is the structure the only structure that we can possibly have? This issue was raised by some intelligent people in this industry and R&D was conducted accordingly. Research shows that some special shape of holes in certain locations of the saw blanks can not only avoid deformation, but also reduce the power consumption and noise, as well as improve the sharpness and lifespan of the blades. According to the data provided by one director of the board of a company (engineering PhD) who has been engaged with saw blade technology for a long time, for the 350 mm blades and smaller ones, the sharpness can be improved by 15%,and lifespan expanded by 20%. He also provided some comparison data for two 3000 mm saw blades (thickness of the segments 12 mm) either with or without holes as shown in figure 2.   The two blades were experimented under exactly the same conditions: the same cutting machine, cutting speed, depth of cut, cooling conditions, cutting work piece. From the 3 charts of figure 2 we can see that, the load current of the blades with holes was reduced by 38.3% in comparison to regular blades and the cutting seam reduced by 11.8%, segment wear loss went down by 58.3%. Therefore, satisfactory results were achieved by lowering the power consumption, saving the stone, as well as expending the lifespan of the blades. When saw blanks have holes: (1) It reduces the selfweight and the cutting machine load. (2) It improves the stress situation. More spaces were created for stress release when cutting. Therefore, deformation caused by external forces and consequently scratching could be avoided. (3) The hole helps to speed up the flow of the air, more cold water can be brought to the cutting seam, therefore help for cooling as well as the chip removal effect. This structure has improved the operational performance of saw blades, expended the lifespan, and reduced the cutting noise. Therefore, it has been widely applied.  1.2.2.2 Grinding and cutting tools for machining Along with the shift of the world’[KG-*4]s manufacturing center to China, different international advanced highperformance grinding and cutting machines were brought to China. Along with these machines, a large number of highperformance, highprecision grinding and cutting tools are needed which has promoted the technological advancement of superabrasives industry in return. In recent years, a number of international highlevel products have been developed and have met the demands of manufacturing industry.  (1) The highspeed, highprecision and highefficiency ceramics CBN grinding wheels with the line speed 125 m/s were developed and put in the market after 2003. They have been used processing the cast steel, carbon steel, alloy steel, bearing steel crankshaft and camshaft in the automobile, motorcycle, textile industries. We have reached the following conclusions by comparing the Chinese grinding wheels with the original imported grinding wheels together with the machine under exacting same conditions: When polishing the chilled cast iron camshaft of automobiles, the performances are exactly the same. When polishing 45# steel camshaft of automobiles, lifespan of the Chinese grinding wheels is around 90% of that of the imported ones and others are the same. When polishing 55# steel camshaft of motorcycles, lifespan of the Chinese grinding wheels is around 85% of the imported ones and rest are the same. When polishing 45# steel camshaft of diesel engines, lifespan of the Chinese grinding wheels is around 80% of the imported ones and rest are the same. However, due to the price and service advantages of the Chinese grinding wheels, the average workpiece grinding cost has been reduced by over 30% in comparison to that of the imported ones[20],and has been well received by the customers. The highspeed, highprecision and highperformance CBN grinding wheels with line speed 160 m/s can be supplied in bulk quantity. However, the number of domestic clients who own 160 m/s machines are limited,therefore they can not be widely used in China. (2) The highprecision, superthin grinding wheels for highprecision cutting and slotting purposes for IC and IT industries. Two types of this line of products were launched in small quantities in 2002. Since then, 5 series of products with a variety of specifications were developed and launched to the market in big quantities as shown in table 4[21,22]. The applications of these products are shown in table 5

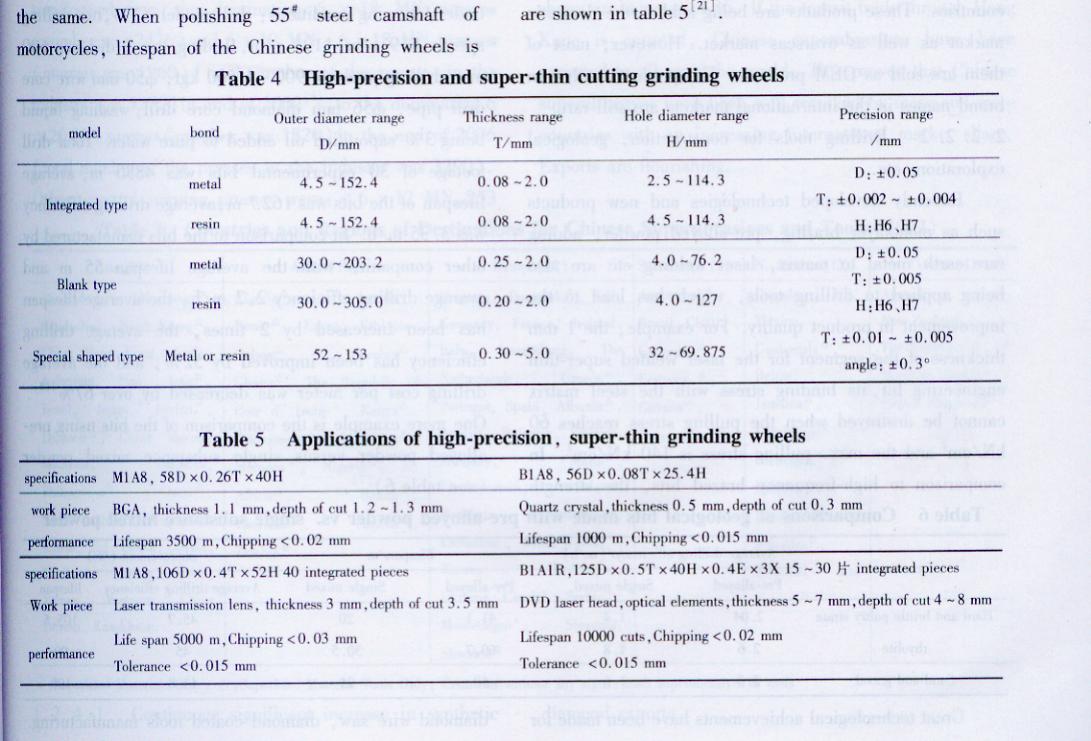

The two blades were experimented under exactly the same conditions: the same cutting machine, cutting speed, depth of cut, cooling conditions, cutting work piece. From the 3 charts of figure 2 we can see that, the load current of the blades with holes was reduced by 38.3% in comparison to regular blades and the cutting seam reduced by 11.8%, segment wear loss went down by 58.3%. Therefore, satisfactory results were achieved by lowering the power consumption, saving the stone, as well as expending the lifespan of the blades. When saw blanks have holes: (1) It reduces the selfweight and the cutting machine load. (2) It improves the stress situation. More spaces were created for stress release when cutting. Therefore, deformation caused by external forces and consequently scratching could be avoided. (3) The hole helps to speed up the flow of the air, more cold water can be brought to the cutting seam, therefore help for cooling as well as the chip removal effect. This structure has improved the operational performance of saw blades, expended the lifespan, and reduced the cutting noise. Therefore, it has been widely applied.  1.2.2.2 Grinding and cutting tools for machining Along with the shift of the world’[KG-*4]s manufacturing center to China, different international advanced highperformance grinding and cutting machines were brought to China. Along with these machines, a large number of highperformance, highprecision grinding and cutting tools are needed which has promoted the technological advancement of superabrasives industry in return. In recent years, a number of international highlevel products have been developed and have met the demands of manufacturing industry.  (1) The highspeed, highprecision and highefficiency ceramics CBN grinding wheels with the line speed 125 m/s were developed and put in the market after 2003. They have been used processing the cast steel, carbon steel, alloy steel, bearing steel crankshaft and camshaft in the automobile, motorcycle, textile industries. We have reached the following conclusions by comparing the Chinese grinding wheels with the original imported grinding wheels together with the machine under exacting same conditions: When polishing the chilled cast iron camshaft of automobiles, the performances are exactly the same. When polishing 45# steel camshaft of automobiles, lifespan of the Chinese grinding wheels is around 90% of that of the imported ones and others are the same. When polishing 55# steel camshaft of motorcycles, lifespan of the Chinese grinding wheels is around 85% of the imported ones and rest are the same. When polishing 45# steel camshaft of diesel engines, lifespan of the Chinese grinding wheels is around 80% of the imported ones and rest are the same. However, due to the price and service advantages of the Chinese grinding wheels, the average workpiece grinding cost has been reduced by over 30% in comparison to that of the imported ones[20],and has been well received by the customers. The highspeed, highprecision and highperformance CBN grinding wheels with line speed 160 m/s can be supplied in bulk quantity. However, the number of domestic clients who own 160 m/s machines are limited,therefore they can not be widely used in China. (2) The highprecision, superthin grinding wheels for highprecision cutting and slotting purposes for IC and IT industries. Two types of this line of products were launched in small quantities in 2002. Since then, 5 series of products with a variety of specifications were developed and launched to the market in big quantities as shown in table 4[21,22]. The applications of these products are shown in table 5  (3) Silicon wafer thinning grinding wheels for electronic components[21].This product was introduced to the market in 2005. Now 6A2 or 6A2H, 6A2T, three elliptical shaped 6A2T grinding wheels, as well as 1A1 shaped silicon wafer thinning ceramics and resin bonded grinding wheels for coarse grinding and fine grinding are available. The size range is: diameter 40~350 mm,thickness:5~45 mm,hole diameter:18.[KG-*4]7~235 mm. These grinding wheels have been used in silicon wafer production lines in nearly 20 companies. Experimental evidence: ceramics grinding wheels for coarse grinding purpose can process 55,000 pieces of 4 inch discrete components, 55, 000 pieces of 6 inch integrated circuits. Resin bond grinding wheels for precise grinding purpose can process 60,000 pieces of 4 inch discrete components, and 10,000 pieces of 6 inch integrated circuits. The processing quality and efficiency both can meet the customers’ requirements.  There are a number of hightech products with the quality reaching that of the products from advanced countries. These products are being sold to the domestic market as well as overseas market. However, most of them are sold as OEM products. The products with own brand names in the international markets are still rare. 2.2.2.2Drilling tools for construction, geological explorations etc.  Recently developed technologies and new products such as monolayer brazing, prealloyed powder, adding rare earth metal to matrix, laser welding etc are also being applied to drilling tools, which has lead to the improvement in product quality. For example, the 1 mm thickness of the segment for the laser welded superthin engineering bit,its binding stress with the steel matrix cannot be destroyed when the pulling stress reaches 60 kN/cm2 and the max. pulling stress is 140 kN/cm2. In comparison to highfrequency brazed bits, the strength has been improved 3 times, the production efficiency has been improved 10~15 times, 30% diamonds are saved, height of the segment is increased by 43%, i.e. from 7 mm to 10 mm. The lifespan of the bits is improved by 1/3. The average drilling speed for drilling regular reinforced concrete: 5.[KG-*4]16 cm /min for 63 mm bits; 3.28 cm /min for 108 mm bits[23]. These bits have been commercialized. Moreover, for the newly developed needle shaped alloydiamond compound geological exploration bits, 8 bits drilled 158.48 meters in cobble and gravel formation. The average lifespan of the drills is 19.81 meters, average drilling efficiency 1.89 m/h, average footage per run is 2.3 m. In comparison to regular alloy bits, the lifespan has been improved by nearly 19 times, average drilling efficiency improved by 0.9 times, average footage per revolution improved by 1.3 times. However, the cost is only 25% of that of the latter.[24]. One more example is the electroplated diamond geological bits with added rare earth metal in the plating solution drilling finecrude marble and vein quartz under following conditions: drill model XY4,two drilling speeds:819 r/m,1191 r/m,feeding travel distance 600 mm,drilling pressure 900~1 500 kgf, 50 mm wire core drill pipe, 56 mm diamond core drill,washing liquid being 3% saponified oil added to pure water. Total drill footage of 30 experimental bits was 4880 m,average lifespan of the bits was 162.[KG-*3]7 m,average drilling efficiency was 3.35 m/h. In comparison to the bits manufactured by other companies with the average lifespan 55 m and average drilling efficiency 2.2 m/h, the average lifespan has been increased by 2 times, the average drilling efficiency has been improved by 52%, and the average drilling cost per meter was decreased by over 67%[25]. One more example is the comparison of the bits using prealloyed powder versus single substance mixed powder (see table 6)

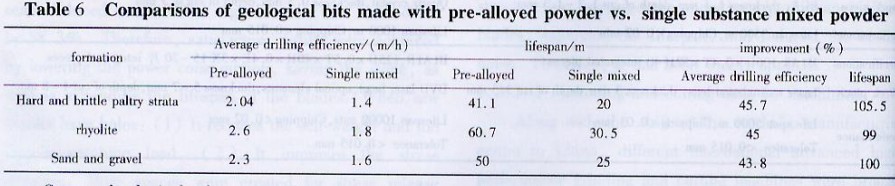

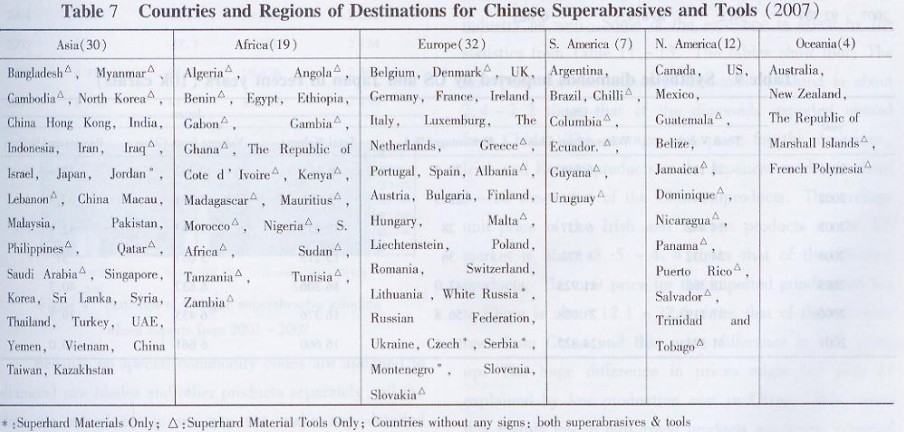

(3) Silicon wafer thinning grinding wheels for electronic components[21].This product was introduced to the market in 2005. Now 6A2 or 6A2H, 6A2T, three elliptical shaped 6A2T grinding wheels, as well as 1A1 shaped silicon wafer thinning ceramics and resin bonded grinding wheels for coarse grinding and fine grinding are available. The size range is: diameter 40~350 mm,thickness:5~45 mm,hole diameter:18.[KG-*4]7~235 mm. These grinding wheels have been used in silicon wafer production lines in nearly 20 companies. Experimental evidence: ceramics grinding wheels for coarse grinding purpose can process 55,000 pieces of 4 inch discrete components, 55, 000 pieces of 6 inch integrated circuits. Resin bond grinding wheels for precise grinding purpose can process 60,000 pieces of 4 inch discrete components, and 10,000 pieces of 6 inch integrated circuits. The processing quality and efficiency both can meet the customers’ requirements.  There are a number of hightech products with the quality reaching that of the products from advanced countries. These products are being sold to the domestic market as well as overseas market. However, most of them are sold as OEM products. The products with own brand names in the international markets are still rare. 2.2.2.2Drilling tools for construction, geological explorations etc.  Recently developed technologies and new products such as monolayer brazing, prealloyed powder, adding rare earth metal to matrix, laser welding etc are also being applied to drilling tools, which has lead to the improvement in product quality. For example, the 1 mm thickness of the segment for the laser welded superthin engineering bit,its binding stress with the steel matrix cannot be destroyed when the pulling stress reaches 60 kN/cm2 and the max. pulling stress is 140 kN/cm2. In comparison to highfrequency brazed bits, the strength has been improved 3 times, the production efficiency has been improved 10~15 times, 30% diamonds are saved, height of the segment is increased by 43%, i.e. from 7 mm to 10 mm. The lifespan of the bits is improved by 1/3. The average drilling speed for drilling regular reinforced concrete: 5.[KG-*4]16 cm /min for 63 mm bits; 3.28 cm /min for 108 mm bits[23]. These bits have been commercialized. Moreover, for the newly developed needle shaped alloydiamond compound geological exploration bits, 8 bits drilled 158.48 meters in cobble and gravel formation. The average lifespan of the drills is 19.81 meters, average drilling efficiency 1.89 m/h, average footage per run is 2.3 m. In comparison to regular alloy bits, the lifespan has been improved by nearly 19 times, average drilling efficiency improved by 0.9 times, average footage per revolution improved by 1.3 times. However, the cost is only 25% of that of the latter.[24]. One more example is the electroplated diamond geological bits with added rare earth metal in the plating solution drilling finecrude marble and vein quartz under following conditions: drill model XY4,two drilling speeds:819 r/m,1191 r/m,feeding travel distance 600 mm,drilling pressure 900~1 500 kgf, 50 mm wire core drill pipe, 56 mm diamond core drill,washing liquid being 3% saponified oil added to pure water. Total drill footage of 30 experimental bits was 4880 m,average lifespan of the bits was 162.[KG-*3]7 m,average drilling efficiency was 3.35 m/h. In comparison to the bits manufactured by other companies with the average lifespan 55 m and average drilling efficiency 2.2 m/h, the average lifespan has been increased by 2 times, the average drilling efficiency has been improved by 52%, and the average drilling cost per meter was decreased by over 67%[25]. One more example is the comparison of the bits using prealloyed powder versus single substance mixed powder (see table 6)  Great technological achievements have been made for diamond wire saw, diamond coated tools manufacturing. As there are a great variety of new products being developed, this paper does not cover the details. 1.2.3 Significant improvements in press manufacturing technology facilitating the advancements in synthetic diamond manufacturing First of all, computer finite element computation and computer simulation were adopted for press design which has improved the design veracity, precision and speed. Secondly, the structure has been changed from flange support to underside support and double support which has increased the strength of the press. Thirdly, the steel for making presses transformed from regular steel to CrMo and NiCrMo which has also improved the strength of the press. Fourthly, the advancements of casting technology and manufacturing technology has improved the static geometric precision and dynamic motion precision etc. All of above mentioned factors have facilitated the overall manufacturing level of presses and have laid the technological foundation for the continuous enlargement of presses. The presses have been transformed from the dominating 6×18 MN presses(number was 2476)and 6×10 MN~6×18 MN presses(number was 1960)(total number of the presses in the industry was 5270)in end of 2002[4],to the dominating 6×20 MN presses(number was 1820)in the end of 2006(total number of the presses in the industry was 3290). Other types of running presses were:≤6×12 MN,253 setsï¼›6×13 MN~6×18 MN,1020 setsï¼›≥6×30 MN,197 sets[26] in 2006. The current trend is that more and more 6×25 MN and 6×32 MN presses are being installed. Some 6×40 MN presses have been installed and designing for 6×44 MN presses is finished. The continuous enlargement of presses lays a solid foundation for highgrade synthetic diamond manufacturing. The continuous improvements in presses and synthetic diamonds have helped to upgrade the image of Chinese synthetic diamond industry. A very rare occasion in the world’s manufacturing industry has happened that some renowned international companies have purchased the Chinese cubic presses in a large quantity and synthetic diamonds were being produced referring to the Chinese production technology. 1.2.4 More and more exports to expanding international markets Table 7 shows that, Superhard materials and relevant products have been exported to 104 countries and regions in 2007[27]. While in 2002 this number was 68, which shows an increase of 36. If the transit trade through Hong Kong is counted, Chinese superabrasives have been exported to all over the world. This proves that Chinese superabrasives have been well received by more and more countries with an increasing international market share. Exports are flourishing.

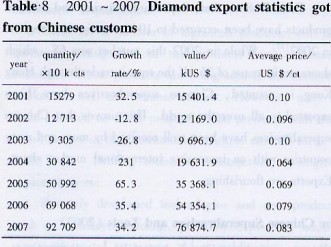

Great technological achievements have been made for diamond wire saw, diamond coated tools manufacturing. As there are a great variety of new products being developed, this paper does not cover the details. 1.2.3 Significant improvements in press manufacturing technology facilitating the advancements in synthetic diamond manufacturing First of all, computer finite element computation and computer simulation were adopted for press design which has improved the design veracity, precision and speed. Secondly, the structure has been changed from flange support to underside support and double support which has increased the strength of the press. Thirdly, the steel for making presses transformed from regular steel to CrMo and NiCrMo which has also improved the strength of the press. Fourthly, the advancements of casting technology and manufacturing technology has improved the static geometric precision and dynamic motion precision etc. All of above mentioned factors have facilitated the overall manufacturing level of presses and have laid the technological foundation for the continuous enlargement of presses. The presses have been transformed from the dominating 6×18 MN presses(number was 2476)and 6×10 MN~6×18 MN presses(number was 1960)(total number of the presses in the industry was 5270)in end of 2002[4],to the dominating 6×20 MN presses(number was 1820)in the end of 2006(total number of the presses in the industry was 3290). Other types of running presses were:≤6×12 MN,253 setsï¼›6×13 MN~6×18 MN,1020 setsï¼›≥6×30 MN,197 sets[26] in 2006. The current trend is that more and more 6×25 MN and 6×32 MN presses are being installed. Some 6×40 MN presses have been installed and designing for 6×44 MN presses is finished. The continuous enlargement of presses lays a solid foundation for highgrade synthetic diamond manufacturing. The continuous improvements in presses and synthetic diamonds have helped to upgrade the image of Chinese synthetic diamond industry. A very rare occasion in the world’s manufacturing industry has happened that some renowned international companies have purchased the Chinese cubic presses in a large quantity and synthetic diamonds were being produced referring to the Chinese production technology. 1.2.4 More and more exports to expanding international markets Table 7 shows that, Superhard materials and relevant products have been exported to 104 countries and regions in 2007[27]. While in 2002 this number was 68, which shows an increase of 36. If the transit trade through Hong Kong is counted, Chinese superabrasives have been exported to all over the world. This proves that Chinese superabrasives have been well received by more and more countries with an increasing international market share. Exports are flourishing.  1.2.4.1 Continuous significant increase in synthetic diamond exports Statistics for Chinese synthetic diamond exports from 2001 to 2007 got from Chinese Customs are shown in table 8. This table shows that the lowest growth rate for synthetic diamond exports in recent years was as high as 32.5%(Except for the negative growth in 2002 and 2003 because synthetic diamonds were exported the same way as the natural diamonds in that period. The exportation procedures were not working well, many orders got delayed or had to be cancelled, and some companies were exporting through other channels during that time). The fact that synthetic diamond exports has increased by more than 5.[KG-*4]1 times from 2001 to 2007 shows that Chinese synthetic diamonds are being accepted by more and more international customers. More and more Chinese synthetic diamonds are being exported to the expanding international markets. However, the overall unit price shows a downturn.

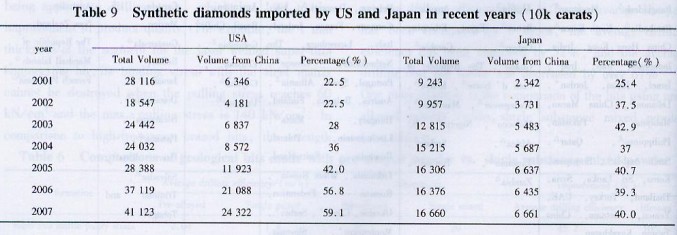

1.2.4.1 Continuous significant increase in synthetic diamond exports Statistics for Chinese synthetic diamond exports from 2001 to 2007 got from Chinese Customs are shown in table 8. This table shows that the lowest growth rate for synthetic diamond exports in recent years was as high as 32.5%(Except for the negative growth in 2002 and 2003 because synthetic diamonds were exported the same way as the natural diamonds in that period. The exportation procedures were not working well, many orders got delayed or had to be cancelled, and some companies were exporting through other channels during that time). The fact that synthetic diamond exports has increased by more than 5.[KG-*4]1 times from 2001 to 2007 shows that Chinese synthetic diamonds are being accepted by more and more international customers. More and more Chinese synthetic diamonds are being exported to the expanding international markets. However, the overall unit price shows a downturn.  According to the statistics got from Chinese Customs, US, Japan, and China Hong Kong are the main destinations for synthetic diamonds. Limited synthetic diamonds are consumed in Hong Kong while Hong Kong mainly reexports the synthetic diamonds to the rest of the world. In the following, we will analyze the imports by US and Japan in recent years. From table 9[28,29]we can see that,China is exporting more and more synthetic diamonds to these two countries. The quantity exported to the US accounts for 59.1% of US's total imports and 40% of Japan's total imports in 2007. Figure 3 shows the changes of the top 5 countries exporting synthetic diamonds which are bigger than 80 mesh after year 2003[28]. Figure 3 shows that China and Ireland are dominating the market. In 2006 and 2007 the market share was over 80%. This kind of products is used for sawing, cutting and drilling tools with high strength. After becoming neck to neck with Ireland in 2005 for the first time, China has outgrown Ireland in the recent couple of years by 20%. This proves that the quality of China's saw grits have been improved and accepted by more and more American users. Though Korea's market share is low but is increasing. Ukraine and Russia's market shares are decreasing. Hong Kong's decreasing market share means that transit trade is being more and more replaced by direct trade.

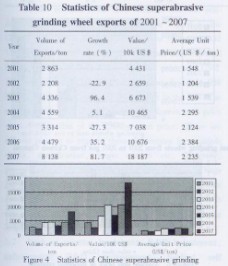

According to the statistics got from Chinese Customs, US, Japan, and China Hong Kong are the main destinations for synthetic diamonds. Limited synthetic diamonds are consumed in Hong Kong while Hong Kong mainly reexports the synthetic diamonds to the rest of the world. In the following, we will analyze the imports by US and Japan in recent years. From table 9[28,29]we can see that,China is exporting more and more synthetic diamonds to these two countries. The quantity exported to the US accounts for 59.1% of US's total imports and 40% of Japan's total imports in 2007. Figure 3 shows the changes of the top 5 countries exporting synthetic diamonds which are bigger than 80 mesh after year 2003[28]. Figure 3 shows that China and Ireland are dominating the market. In 2006 and 2007 the market share was over 80%. This kind of products is used for sawing, cutting and drilling tools with high strength. After becoming neck to neck with Ireland in 2005 for the first time, China has outgrown Ireland in the recent couple of years by 20%. This proves that the quality of China's saw grits have been improved and accepted by more and more American users. Though Korea's market share is low but is increasing. Ukraine and Russia's market shares are decreasing. Hong Kong's decreasing market share means that transit trade is being more and more replaced by direct trade.  1.2.4.2 Increasing trend for superabrasive grinding wheel exports Statistics of Chinese superabrasive grinding wheel exports from 2001~2007 got from Chinese Customs are shown in Table 10 and Figure 4. Though the table shows a fluctuating growth trend in recent years, it still shows an overall increasing trend. The exports in 2007 were 2.8 times bigger than those of 2001, which is lower than the synthetic diamond export growth rate.

1.2.4.2 Increasing trend for superabrasive grinding wheel exports Statistics of Chinese superabrasive grinding wheel exports from 2001~2007 got from Chinese Customs are shown in Table 10 and Figure 4. Though the table shows a fluctuating growth trend in recent years, it still shows an overall increasing trend. The exports in 2007 were 2.8 times bigger than those of 2001, which is lower than the synthetic diamond export growth rate.

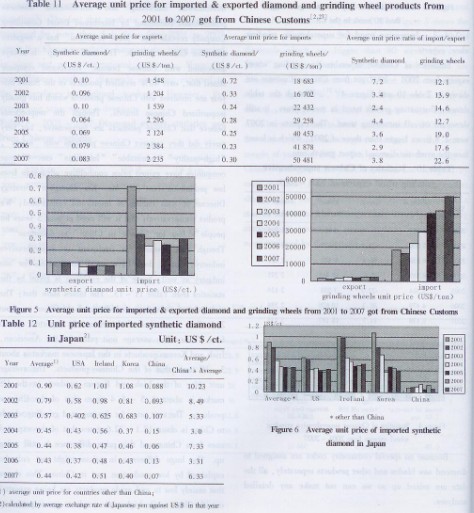

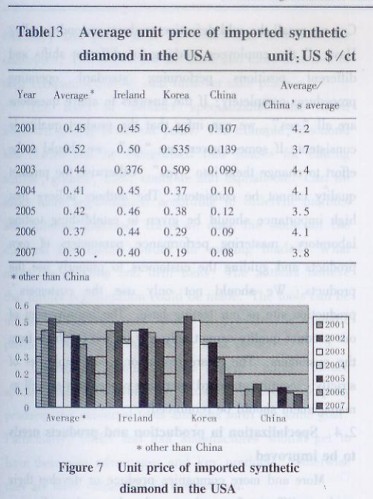

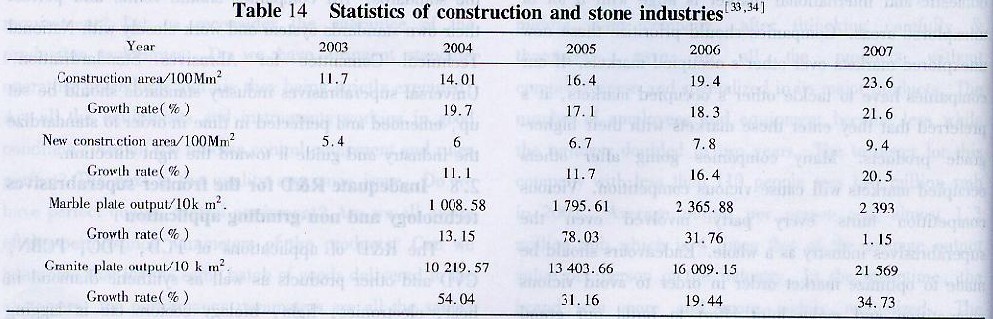

Because no special commodity codes are assigned to diamond saw blades and other products separately, all the data are mixed up so we can not make any detailed analyses.  [HS(3][WT4”HZ]2 Major problems and shortcomings existing in our industry’s development[WT][HS)] We have to realize our shortcomings while we are making achievements in order to identify the gaps and set forth our goals. 2.1 Unmet domestic needs due to low percentage of highgrade products with brand names An online questionnaire participated by 569 international marketing and international business professionals conducted by Interbrand Brand Consulting Company reveals that “Made in China” has a negative effect for Chinese brands. The word “cheap” is always associated with Chinese brands. Interbrand company stated that, over 40% recalled products in the States this year are involved with Chinese products which has greatly jeopardized Chinese brands. Though the respondents believe that Chinese products are inexpensive, but very rarely did they connect Chinese products with “safety”, “highquality” “admirable” “luxurious” etc. Chinese companies have gained price competitive advantage from low production cost ... Mr. Xia Zhongsen, Strategy Director of Asia Pacific of Interbrand commented: We predict conservatively that it will need at least 5 years for people’[KG-*4]s fear for “Made in China” to disappear[30]. Though this research is irrelevant to superabrasives industry, but it does have some implications for our industry as well. Some of the evidence is given by the statistics from Table 11~13. The tables show that: The unit price for the imported diamonds to China is about 2.4~7.2  times that of the diamonds exported abroad from China. The average unit price for the American, Irish and Korean products in the Japanese market is about 3~10 times that of the Chinese products. The average unit price of the Irish and Korean products in the US market is about 3.5~4.4 times that of the Chinese products. The unit price for the imported grinding wheels to China is about 12.[KG-*4]1~22.[KG-*4]6 times that of the exported ones from China and this price difference is still going up. The huge difference in prices might not only be explained by low production cost in China. This shows that mainly low to mid grade products are being exported outside China while highgrade products are imported to China with high technical content. Both the international and domestic highend markets are still dominated by developed countries while China plays only an insignificant role in these markets. The brands associated with “safety” “highquality”, “admirable”, “luxurious” are even rarer in China. Some imported products are actually Chinese products in origin but repacked with renowned brand labels and reexported to China. This shows the importance of having famous brand names. Though we are making progress, our international counterparts are also making progress and we are still not of the same calibre as them. Chinese entrepreneurs especially those from large enterprises should change the mentality from blindly seeking for large scale, pursuing quantity over quality to high efficiency, high value added etc. They should be making effort to build well known international brand names for Chinese superabrasives.

Because no special commodity codes are assigned to diamond saw blades and other products separately, all the data are mixed up so we can not make any detailed analyses.  [HS(3][WT4”HZ]2 Major problems and shortcomings existing in our industry’s development[WT][HS)] We have to realize our shortcomings while we are making achievements in order to identify the gaps and set forth our goals. 2.1 Unmet domestic needs due to low percentage of highgrade products with brand names An online questionnaire participated by 569 international marketing and international business professionals conducted by Interbrand Brand Consulting Company reveals that “Made in China” has a negative effect for Chinese brands. The word “cheap” is always associated with Chinese brands. Interbrand company stated that, over 40% recalled products in the States this year are involved with Chinese products which has greatly jeopardized Chinese brands. Though the respondents believe that Chinese products are inexpensive, but very rarely did they connect Chinese products with “safety”, “highquality” “admirable” “luxurious” etc. Chinese companies have gained price competitive advantage from low production cost ... Mr. Xia Zhongsen, Strategy Director of Asia Pacific of Interbrand commented: We predict conservatively that it will need at least 5 years for people’[KG-*4]s fear for “Made in China” to disappear[30]. Though this research is irrelevant to superabrasives industry, but it does have some implications for our industry as well. Some of the evidence is given by the statistics from Table 11~13. The tables show that: The unit price for the imported diamonds to China is about 2.4~7.2  times that of the diamonds exported abroad from China. The average unit price for the American, Irish and Korean products in the Japanese market is about 3~10 times that of the Chinese products. The average unit price of the Irish and Korean products in the US market is about 3.5~4.4 times that of the Chinese products. The unit price for the imported grinding wheels to China is about 12.[KG-*4]1~22.[KG-*4]6 times that of the exported ones from China and this price difference is still going up. The huge difference in prices might not only be explained by low production cost in China. This shows that mainly low to mid grade products are being exported outside China while highgrade products are imported to China with high technical content. Both the international and domestic highend markets are still dominated by developed countries while China plays only an insignificant role in these markets. The brands associated with “safety” “highquality”, “admirable”, “luxurious” are even rarer in China. Some imported products are actually Chinese products in origin but repacked with renowned brand labels and reexported to China. This shows the importance of having famous brand names. Though we are making progress, our international counterparts are also making progress and we are still not of the same calibre as them. Chinese entrepreneurs especially those from large enterprises should change the mentality from blindly seeking for large scale, pursuing quantity over quality to high efficiency, high value added etc. They should be making effort to build well known international brand names for Chinese superabrasives.