Flexible Honing Has Custom Engine Producer Thriving

Post Date: 18 Jul 2014 Viewed: 372

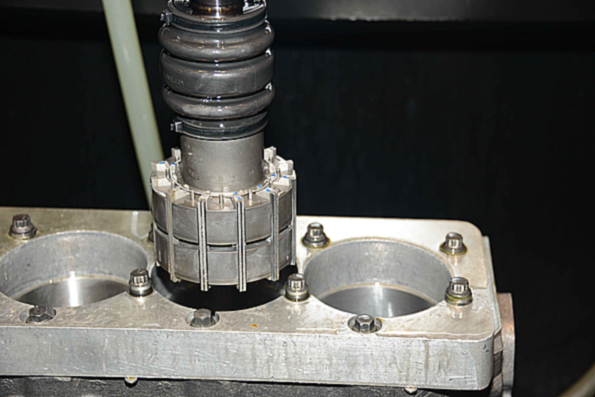

Sunnen’s two-stage diamond abrasive honing tool does roughing and finishing with 220- and 500-grit abrasive without pause for stone change. The advanced control system on the SV-20 allows Dart Machinery to achieve a wide range of finishes with these two abrasives.

A new SV-20 honing system from Sunnen Products performs high-precision, highly flexible honing for a range of block designs and metallurgies in a single continuous process, with no need for stone change, he reported. The American-made SV-20 replaced a more expensive, European-built honing system that “just wasn’t a good fit for our production, not flexible enough,” said Maskin.

Maskin started Dart in 1981 in a two-car garage in Oak Park, Mich., and has grown it into a manufacturing leader in racing and high-performance engine blocks, heads, and other components. The company does its part to preserve Detroit as the “Motor City,” with a technology center and manufacturing facility in the metro area.

Today, 95 Dart employees make about 8,000 blocks and 16,000 heads per year for drag racing, circle track racing, road racing, and high-performance custom cars, as well as marine and industrial power applications.

”We produce custom in volume,” Maskin explained. Blocks are manufactured to customer order in type and material, bore spacing, cam location, bolt pattern, deck height, lifter location, oil pan bolt pattern, metric or U.S. dimensions – “just infinite variation and specialization,” he said.

Dart makes blocks in various grades of iron (including CGI) and in aluminum with iron-sleeved cylinder bores, including blocks machined from forged and heat-treated aluminum billets. The manufacturing plant operates three shifts, 6 or 7 days per week depending on production volume, with 26 large-dimension Makino CNCs churning out blocks, heads, and manifolds.

Customers choose among seven different base block designs, big-block and small-block sizes, all evolved from NHRA pro-stock V-8 experience. “That’s where all the technology comes from,” said Maskin, whose own engine creations achieved drag-racing’s first 300 mph quarter-mile run and four-second Funny Car elapsed time.

Applying the same creativity to honing, Dart combines two advanced technologies – diamond honing abrasives driven with a programmable spindle, followed by profilometers to measure the variability in cylinder surface finishes – to replicate “best” block finishes and ring seal.

"Honing is all about sealing the rings to the cylinder wall," Dick Maskin stressed. "The key is valley depth: Too deep and you have too much oil in it, slowing the engine down with friction. Too little valley, and the rings can hydroplane across the valleys and you lose seal. Then, you have to run thicker oil. Unless oil can reside in the valleys, it sits on the cylinder wall and must be thick not to be torn off by the rings. We think valleys need to be in the mid to high 30 micro inches (0.000030 in.) to really seal a race engine strongly, and deeper in the mid to high 40's for a more conventional engine.

"For some blocks using today’s steel rings, we hone for peaks of 12-15 micro inches (.000012-15 in.) or smoother. When we turn the short block over manually with a wrench, the rings will knock the peaks down to 5 or less before we ever start the engine, but the valleys remain. We may not always take the peaks off during honing. If you ball-hone or sandpaper, thinking you'll accomplish this, you’ll simply reduce valley depth and the engine won’t run as good.

"In our experience, if you go smoother on honing peaks and valleys, the finish won’t last as long. Starting with a rougher finish, the block is going to wear in and be sealed up so tight it will surprise you."