Tailor Made End Mills Now Available For Aluminium Parts

Post Date: 27 Aug 2014 Viewed: 332

Manufacturers or machine shops needing a specific corner radius or a cutter with a special tool length to keep overhang to a minimum, can now take advantage of the new Sandvik Coromant Tailor Made offer for CoroMill Plura end mills. Anyone machining ISO N (aluminium) workpieces can easily acquire customized solid cutters to fit specific application requirements.

Page Content

Many specific aluminium component challenges exist in sectors such as aerospace and motorsport. Here, parts are often extremely complex and made in small batches or even one-offs. Standard stocked tools are often not available if the sizes or dimensions are very definitive.

Thanks to Tailor Made CoroMill Plura end mills, finding the perfect tool for aluminium parts has never been easier. Quotation within 24 hours, easy ordering and delivery within 10 working days matches up to modern commercial timelines. What’s more, the whole process can be facilitated online: customers can find Tailor Made forms at www.sandvik.coromant.com

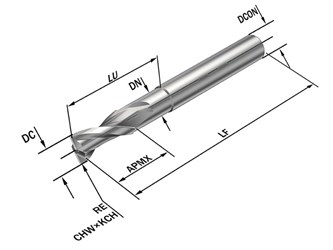

So what precisely can be achieved? Well, it is possible to adjust the corner radius of a tool to meet component requirements, for instance. Similarly, where vibration and/or stability is the issue, tool length can be optimized to reduce overhang to an absolute minimum.

For operations with inadequate clearance it is also possible to modify the usable length of the end mill to provide sufficient clearance between the workpiece and the tool. Other factors that can be modified include cutting diameter, number of teeth, helix angle, shank type, shank diameter and neck diameter.

Tailor Made CoroMill Plura end mills can be used for all types of operation, from roughing to finishing, and super-finishing, in both aluminium and thermoplastic materials. The cutters can be deployed for slotting, shoulder milling and profiling. Of course, the customer will also enjoy all the usual benefits of using Sandvik Coromant cutters, including a wide choice of outstanding cutter geometries and long tool life at high material removal rates.