Why Diamond Segments Have Different Shapes

Post Date: 04 Dec 2009 Viewed: 853

The shape of diamond segments is an important factor influencing the performance of diamond blades. The different shapes are directly related to cutting efficiency and the ratio of the diamonds’ non-normal failure.

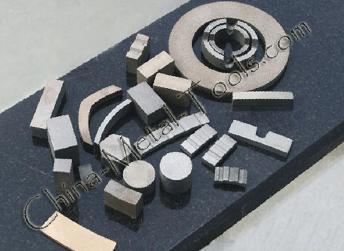

Currently, there are many kinds of shape diamond segments, for example, convex segments, layered sandwich concave segments, L-shape segments, step-shape segments, segmented segments and side-slotted segments.

The designing for the shape and structure of diamond segments mainly has two purposes. The first is to improve the containing and discharging sawdust capabilities and the cooling and lubricating functions of the diamond segments in the cutting arc. The second is to reduce the friction between the segments and stone (or other material) and sawdust, and improve the blade’s cutting capability, and then save energy and improve the blade’s performance.

As there are slots on the rim of diamond blades, the length of diamond segments also influences the blade’ performance. In sawing, the diamonds on the front of the segment, which enter the cutting arc earlier, bear more loads than the diamonds on the back of the segment. Therefore we can segment the diamond segments properly, so that the performance of the front end and the back end of a diamond segment matches the loads they bear.