Diamond Tools: How to Choose Diamonds' Grit

Post Date: 06 Mar 2010 Viewed: 545

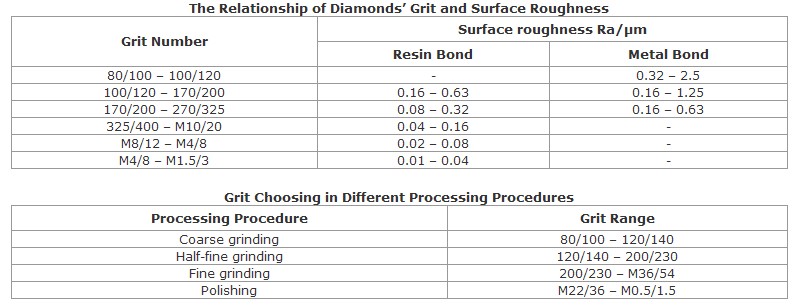

When choosing the diamonds’ grit of a diamond tool, we should consider the workpieces’ roughness requirement, the tool’s cutting/grinding efficiency and the best grit range of the tool’s bond.

Generally, diamond tools with coarse diamond grit have high processing efficiency but will also leading to high processing roughness; diamond tools with fine diamond grit is opposite. For a same roughness requirement, the grit of super-abrasives is finer than the normal-abrasives’. Under the premise of satisfying the roughness requirements, we should choose coarser grit to improve processing efficiency.

Different bonds of diamond tools have different hold capacities to the diamonds. For a certain bond, there is a best grit range. Normally, the best grit for resin bond is finer than 100/120, ceramics bond is 100/120 – 170/200, and metal bond is 70/80 – 230/270.

In addition, metal-plated diamonds have a lower processing roughness, so their grit can be coarser.

Below are two tables we can refer to when choosing the diamonds’ grit for diamond tools: