Scientists Discover Material Harder Than Diamond

Post Date: 16 May 2011 Viewed: 477

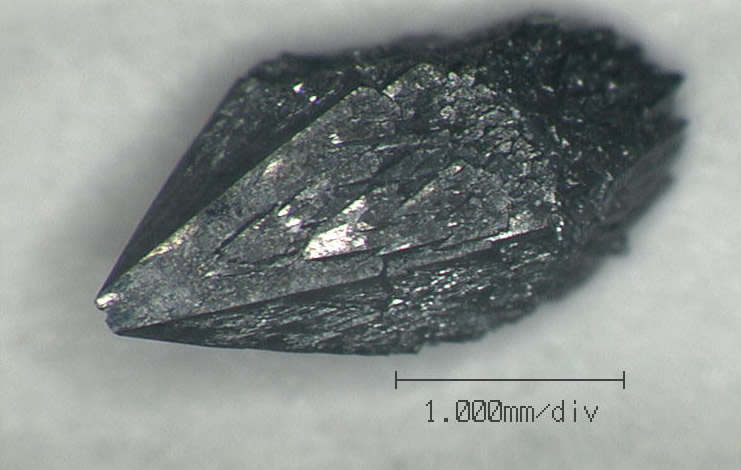

Currently, diamond is regarded to be the hardest known material in the world. But by considering large compressive pressures under indenters, scientists have calculated that a material called wurtzite boron nitride (w-BN) has a greater indentation strength than diamond. The scientists also calculated that another material, lonsdaleite (also called hexagonal diamond, since it’s made of carbon and is similar to diamond), is even stronger than w-BN and 58 percent stronger than diamond, setting a new record.

This analysis marks the first case where a material exceeds diamond in strength under the same loading conditions, explain the study’s authors, who are from Shanghai Jiao Tong University and the University of Nevada, Las Vegas. The study is published in a recent issue of Physical Review Letters.

“The new finding from our results is that large normal compressive pressures under indenters can transform certain materials (such as w-BN and lonsdaleite) into new superhard structures that are harder than diamond,” coauthor Changfeng Chen from the University of Nevada, Las Vegas, told PhysOrg.com. “This is a new mechanism that can be used to design new superhard materials.”

The scientists explain that the superior strength of w-BN and lonsdaleite is due to the materials’ structural reaction to compression. Normal compressive pressures under indenters cause the materials to undergo a structural phase transformation into stronger structures, conserving volume by flipping their atomic bonds. The scientists explain that w-BN and lonsdaleite have subtle differences in the directional arrangements of their bonds compared with diamond, which is responsible for their unique structural reaction.

Under large compressive pressures, w-BN increases its strength by 78 percent compared with its strength before bond-flipping. The scientists calculated that w-BN reaches an indentation strength of 114 GPa (billions of pascals), well beyond diamond’s 97 GPa under the same indentation conditions. In the case of lonsdaleite, the same compression mechanism also caused bond-flipping, yielding an indentation strength of 152 GPa, which is 58 percent higher than the corresponding value of diamond.

“Lonsdaleite is even stronger than w-BN because lonsdaleite is made of carbon atoms and w-BN consists of boron and nitrogen atoms,” Chen explained. “The carbon-carbon bonds in lonsdaleite are stronger than boron-nitrogen bonds in w-BN. This is also why diamond (with a cubic structure) is stronger than cubic boron nitride (c-BN).”

Until recently, normal compressive pressures under indenters have not been included in the calculations of ideal shear strengths of crystals from first principles, but latest developments have enabled researchers to consider their effects, resulting in surprising discoveries like the one shown here. Still, experimenting with w-BN and lonsdaleite will be challenging, since both materials are difficult to synthesize in large quantities. However, another recent study has taken a promising approach to producing nanocomposites of w-BN and c-BN, which may also provide a way to synthesize nanocomposites containing lonsdaleite and diamond.

In addition, by showing the underlying atomistic mechanism that can strengthen some materials, this work may provide new approaches for designing superhard materials. As Chen explained, superhard materials that exhibit other superior properties are highly desirable for applications in many fields of science and technology.

“High hardness is only one important characteristic of superhard materials,” Chen said. “Thermal stability is another key factor since many superhard materials need to withstand extreme high-temperature environments as cutting and drilling tools and as wear, fatigue and corrosion resistant coatings in applications ranging from micro- and nano-electronics to space technology. For all carbon-based superhard materials, including diamond, their carbon atoms will react with oxygen atoms at high temperatures (at around 600°C) and become unstable. So designing new, thermally more stable superhard materials is crucial for high-temperature applications. Moreover, since most common superhard materials, such as diamond and cubic-BN, are semiconductors, it is highly desirable to design superhard materials that are conductors or superconductors. In addition, superhard magnetic materials are key components in various recording devices.”